The state-of-art processing plants for rice production have fully mechanized sophisticated processing procedures for different stages like de-moisturizing, temperature controlled drying, cleaning, de-husking, de-stoning, polishing, sorting and grading. In these hi-tech milling plants every stage conforms to international standards and stringent guidelines of process control are meticulously adhered to at every stage to ensure uniformity of grains without destroying fragrance, aroma and basic quality of grain.

Most of the impurities, irrespective of their sizes and nature are completely removed in different stages of the passage of paddy through fork-like vibrating sieve, scalper suction fan and vibrating sieve incorporated in these machines.

Parboiling Plant : The process of parboiling uses processed soft water obtained from water treatment plant. The plant has specially designed soaking bins with sensor based sophisticated controllers for water temperature. The process is far superior than the conventional methods in terms of mitigating development of unwanted smells and ensures hygienic processing of the grain, preserving its fragrance and aroma during the processing. The requirements of soft water for parboiling process are met by an integrated water treatment plant.

Milling Plant : The three state-of-art milling plants of Modern Rice & General Mills use 21st century technology from Buhler. The online inflow and outflow mechanisms are fully computerized with the help of sensors. The plants have production capacity exceeding 10 tons per hour, and are equipped with number of Pre cleaners, De-stoners, Precision-sizers, Graders, Paddy separators, De-huskers, Magnets etc. The plant premises are environment friendly and fully protected against contamination by foreign particles.

Aspirated Rice Huskers : These high capacity huskers offer high performance and unmatched capability for removing husk from paddy rice. Its unique feeding mechanism gives it the ability to dehusk rice at a greater capacity than conventional huskers while breaking far less rice grain during the process.

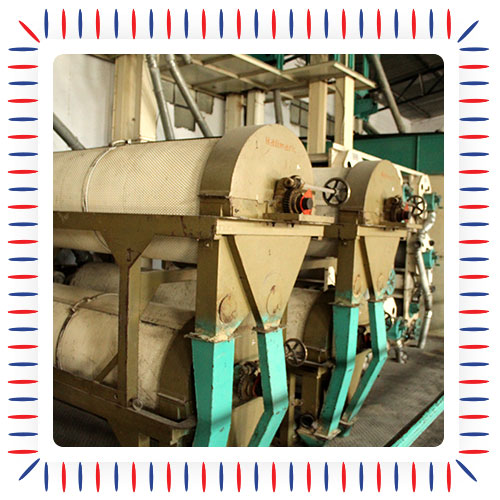

Paddy Separators : This unit removes paddy from brown rice at capacities and efficiencies that are unmatched in the industry. Its three adjustable-position discharge systems coupled with the adjustable separating tray angle, allows flexibility in producing pure brown rice and paddy products.

Plano - Shifters : The requirement of high capacity sizers is met by Plano-Shifters, which ensures uniform grading.

Vertical Abrasive Polisher : The high capacity abrasive whitener offers unmatched efficiency of milling with regard to power savings. Its low milling pressure helps in the maximization of head rice yield, and its ability to function efficiency on both low and hard milling applications makes it an ideal "first break" milling machine.

Colour Sorters : The series of optical sorting machines are used for operational flexibility & define the shade of colour of the grain, as well as the size of the offending spot. Its computer based monitoring system allows online tracking.